Engineering

Vertical Aerospace's engineering staff has extensive capabilities and experience. Our engineers are involved in the repair/manufacturing process from the very beginning to ensure we meet all customer and regulatory requirements.

Our team of engineers designs and substantiates repairs beyond the OEM manual for metallic and non-metallic components. We utilize Leica laser trackers, CATIA and SolidWorks software to aid in repair designs and to ensure that our repair designs meet OEM design criteria. We have experience to develop and design FAA DER approved repairs, STC and PMA components.

In addition, we utilize customer-approved STC (Supplemental Type Certificate) and PMA (Parts Manufacture Approval) components in our repair process.

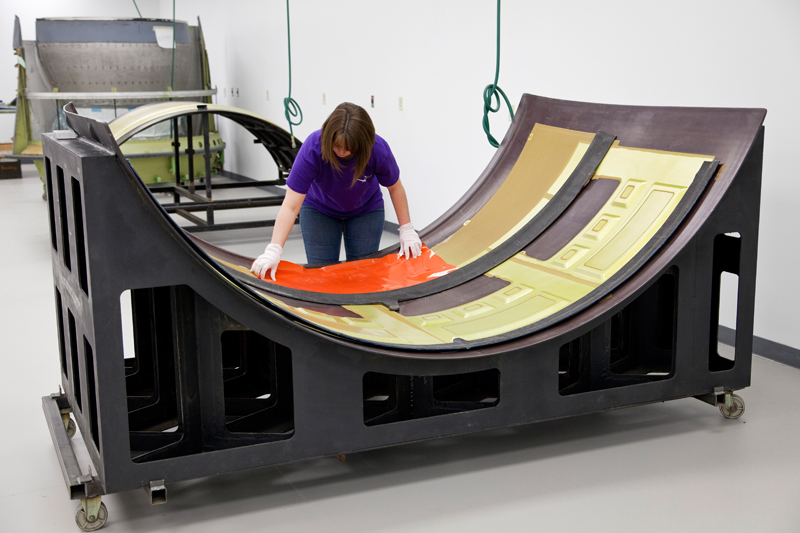

Bonding

Vertical Aerospace’s technical competencies center on the maintenance of metallic and composite bonded honeycomb structures. The company’s capabilities focus on the repair and overhaul of engine nacelle components such as nose cowls, fan cowls, fan reversers and exhaust nozzles. In addition to nacelles, Vertical Aerospace also specializes in the repair and overhaul of flight control surfaces, engine acoustic liners and additional airframe and system-related components.

Vertical Aerospace’s technical competencies center on the maintenance of metallic and composite bonded honeycomb structures. The company’s capabilities focus on the repair and overhaul of engine nacelle components such as nose cowls, fan cowls, fan reversers and exhaust nozzles. In addition to nacelles, Vertical Aerospace also specializes in the repair and overhaul of flight control surfaces, engine acoustic liners and additional airframe and system-related components.

Welding

Vertical Aerospace welders are certified to required aerospace certifications and have extensive industry experience. Our welding group includes equipment used for tungsten inert gas welding (TIG), metal inert gas welding (MIG) as well as Heliarc equipment, all of which allow Vertical to weld all types of materials from exotic metals, titanium, aluminum, and steel.

Alkaline Cleaning & Descaling

Vertical Aerospace has full capability for exhaust and other metal alkaline cleaning and descaling processes. Please reach out if you have a specific process specification not mentioned below and our team will respond quickly.

- GE 70-21-07

- Boeing SOPM 20-30-03

Metal Processing

Phosphoric Acid Anodize (PAA) Line

Vertical Aerospace’s Phosphoric Acid Anodizing (PAA) Line is a critical process in ensuring proper bonding, and is the preferred method of treatment for structural bonding of aluminum alloys.

Vertical Aerospace’s Phosphoric Acid Anodizing (PAA) Line is a critical process in ensuring proper bonding, and is the preferred method of treatment for structural bonding of aluminum alloys.

Vertical Aerospace offers a hot Forest Products Laboratory (FPL) etch, sulfuric acid, sodium dichromate and DI water rinse, also known as “optimized FPL.” Hot FPL is required for most military parts and is preferred by most major airlines.

The FPL etch and PAA process provide the best possible bonding structure available. Vertical Aerospace verifies that our process are in accordance with BAC5555 and BAC5514 by processing and running test coupons along with each part through the entire PAA and autoclave process. Upon completion, Vertical Aerospace performs tensile testing, wedge crack extension tests and rolling drum peel tests on each coupon, as required.

Tooling

Vertical Aerospace is a vertically integrated supplier from tool design to component manufacturing. We have extensive tool fabrication capabilities that include both hard and soft tooling (composite). Utilizing our Leica laser trackers and SolidWorks software, we can design, fabricate and verify completed tooling.

Quality

Vertical Aerospace’s quality management system is ISO 9001:2008 and AS9100 Rev D certified. Our inspection capabilities include Level II NDT technicians utilizing methods such as Florescent Penetrant Inspection (FPI), Magnetic Particle Inspection (MPI), Ultrasonic and Eddy Current.

Vertical Aerospace holds the following certifications:

View our MRO Capabilities Products.